I got back from Wichita Thursday night. I think that will be my last trip there for at least two months. Yesterday I spent a good little while sitting in the cockpit in the dark with two LED flood lights powered up. I tried clamping them down in various locations, looking for the best compromise. I finally decided that the best location was near the canopy bow, just ahead of the end of the canopy rail. I had tried a location further back, hoping to get a more direct line at the instrument panel to get rid of some of the shadows. But that ended up putting the left light in the perfect location to reflect off that big GNS-430 screen and right into my eyes. Not good at all.

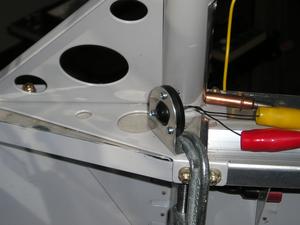

Once I knew where the flood lights were going to be mounted, I finished fabricating the mounting brackets and drilled the holes to bolt them in place and drilled holes to run the wires.

Today I mounted the B&C dimmer module, and was getting ready to start running the wires when I got side-tracked. My eyes fell on the pieces of angle that the avionics trays bolt to. I remembered that two of the bolts didn't yet have nut plates, as I had run out of the type I needed. Those nut plates arrived months ago, but I had never riveted them in place. This job would only get more difficult as more stuff was installed, so I decided to remove enough stuff so I could install them today.

Next I was going to run the wires for the LED flood light, but I realized that the ones coming from the dimmer really needed something to attach them to so they wouldn't flop around. The rear support for the avionics trays would be the perfect place to attach those wires to, but I haven't fabricated it yet. I spent a while with pieces of scrap aluminum and puzzled out a simple, strong and relatively light solution, which I'll fabricate this week.