Plan A for the transition piece between the upper cowling and the plenum chamber didn't work out. Last Sunday night I hardly slept, as I kept waking up with new ideas on how to make this work. I would ponder each idea for awhile, consider its pros and cons, and then fall asleep for a while. By morning I had the germ of Plan B.

Plan B - I remembered that if you use standard cooling baffles, Van provides two curved pieces of fibreglas to be grafted on to the upper cowling inlets. These pieces provide a smooth upper guide for the air as it comes in the inlet and expands into the area above the engine.

Plan B - I remembered that if you use standard cooling baffles, Van provides two curved pieces of fibreglas to be grafted on to the upper cowling inlets. These pieces provide a smooth upper guide for the air as it comes in the inlet and expands into the area above the engine.

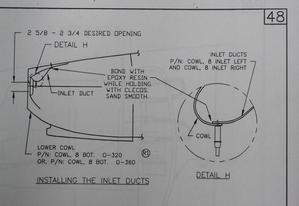

Here you can see the section of the plans that show the inlet ducts, if you use standard baffles.

Here you can see the section of the plans that show the inlet ducts, if you use standard baffles.

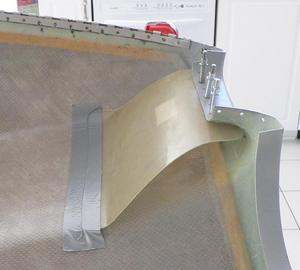

I temporarily clecoed and taped the fibreglas pieces in place (view of upper cowling, upside down).

I temporarily clecoed and taped the fibreglas pieces in place (view of upper cowling, upside down).

I covered the fibreglas with vinyl tape, and used Styrofoam and modelling clay to form a mold for the sides of the right transition piece.

I covered the fibreglas with vinyl tape, and used Styrofoam and modelling clay to form a mold for the sides of the right transition piece.

If the right side shows that this plan will work, then I will make another one for the left side.

I will rivet a piece of aluminum to the upper cowling.

I will rivet a piece of aluminum to the upper cowling.

The fibreglas transition piece will be attached to that piece of aluminum with three screws and nutplates. There will be a piece of rubber from a tire inner tube that will go between the transition piece and the plenum chamber, to form an air tight, but flexible seal.

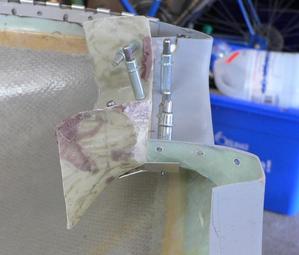

Side view of transition piece clecoed in place.

Side view of transition piece clecoed in place.

Top view of transition piece clecoed in place. The contour on the inner edge (left side of the picture) didn't come out quite right. It ends up too far away from the front wall of the baffles. I've cut it off, and tonight I grafted a new section on. Hopefully this will be better.

Top view of transition piece clecoed in place. The contour on the inner edge (left side of the picture) didn't come out quite right. It ends up too far away from the front wall of the baffles. I've cut it off, and tonight I grafted a new section on. Hopefully this will be better.